Wide electrochemical stability window is reported in Ta-Hf-C electrodes with robust mechanical properties and competitive thermoelectric response. Emerson Coy et al., Chemical Engineering Journal

A high-temperature, highly inert, hard and chemically stable material was developed by the close collaboration of several researchers from the Nanobiomedical centre and the faculty of physics at the Adam Mickiewicz University, also in cooperation with researchers from Gdansk (The Szewalski Institute of Fluid-Flow Machinery), Germany (Max Planck Institute for Polymer Research), Korea (Incheon National University) and Spain (Institute of Materials Science of Barcelona). The material is composed of nanometric Tantalum(Ta) Hafnium(Hf) Carbide crystals which are tightly wrapped inside of an amorphous matrix of similar composition. This material can be deposited over many surfaces by a process called sputtering, a physical method that allows depositing coatings over virtually any material.

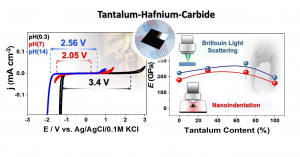

Ta-Hf-C has the highest melting point known to man (>4000°C), and in this study, its large electrochemical stability was studied in a broad range of acidic and basic conditions. The results show that Ta-Hf-C possesses one of the largest electrochemical windows of stability of any solid electrode, above that of glassy carbon, which is considered a commercially available standard electrode. Additionally, researchers investigated the mechanical properties of the electrodes by a unique combined effort using contact techniques (Nanoindetation) and non-destructive ones (Brillouin Light scattering). The combined effort allowed the researchers to show the mechanical and engineering applicability of the material both at the nanoscale and at the macro scale. Ta-Hf-C showed a superior mechanical response, being at least three times harder than steel (hardness), and at least 100 times more resistant to deformation than glassy carbon (elastic modulus). The study has further shown the existence of a small but potentially exploitable thermoelectric effect on the material. This means that some electrical current could be detected under a thermal gradient, which although far from the market standard, could provide unique applicability to the electrodes since the higher the temperature gradient, the higher the current detected. This is especially important when the large thermal stability of Ta-Hf-C is considered (>4000°C), opening the door for high-temperature sensing or other energy-related applications in extreme environmental conditions.

Finally, the electrodes' electrochemical, thermoelectric and mechanical properties can be tuned by controlling their stoichiometry and the ratio between Hf and Ta atoms. This fact provides an additional possibility for customization and exploration of this material.