Roman Zagrodnik , Anna Duber , Krystyna Seifert: Hydrogen production during direct cellulose fermentation by mixed bacterial culture: The relationship between the key process parameters using response surface methodology Journal of Cleaner Production 314 (2021) 127971

The current systems of energy production are based on the fossil fuels, which are not environmentally friendly and its reserves are limited. These aspects have induced the search for new, alternative energy sources, among which hydrogen seems to be very attractive. Hydrogen, which represents a renewable fuel with high heat of combustion of 142,35 kJ g-1, which is three times higher than in case of fuels based on hydrocarbons.

The basic factor determining the application of hydrogen as a fuel is its renewable and environmentally friendly method of production. Research on hydrogen production has led to the development of many methods and among them biological processes attract special attention. The advantages of these processes are: renewable systems, lack of toxic products, mild process conditions, low cost and the possibility of waste utilization, which can serve microorganisms as a source of organic carbon.

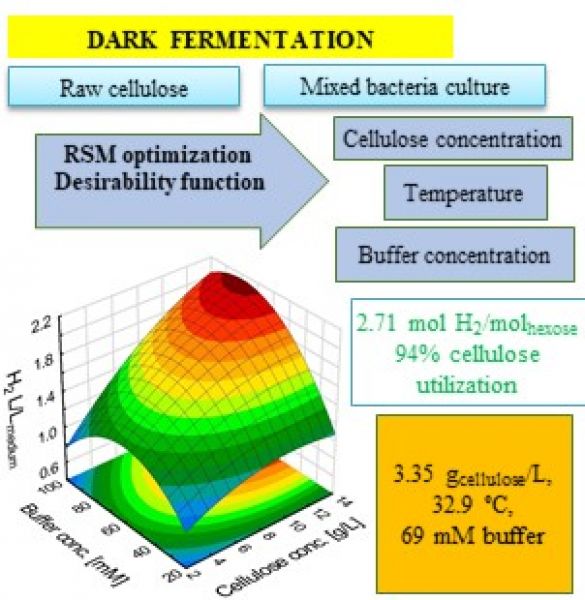

In the publication Dr Roman Zagrodnik and prof. Krystyna Seifert from the Department of Chemical Technology of the Faculty of Chemistry, Adam Mickiewicz University and Dr Anna Duber from the Poznań University of Technology demonstrated that cellulose can be used, without pretreatment, in the process of dark fermentation to hydrogen, with the mixed bacterial culture.

The aim of this study was to determine the optimal values of the following parameters: temperature, phosphate buffer concentration and substrate concentration, using the Response Surface Methodology. These parameters represents the main factors influencing the hydrogen generation and the efficiency of the process. The model indicated that the highest cumulative hydrogen production of 2.14 L H2/Lmedium could be obtained at 13.5 g of cellulose/L, 79.5 mM of buffer and 32.6 ◦C. However, the highest yield efficiency of 2.71 mol H2 / molhexose was achieved with a cellulose concentration of 3.35 g / L and a buffer of 69 mM at 32.9oC. Phosphate concentration above 80 mM decreased H2 production, but had positive effect on cellulose consumption.

The bacterial community analysis showed that Ruminiclostridium papyrosolvens was responsible for cellulose hydrolysis. Lachnoclostridium sp.

could be correlated with ethanol production at high phosphate buffer concentration, while Caproiciproducens sp. with caproate production at low buffer concentration. The obtained results could also serve as a base for the processes of hydrogen and caproate production from lignocellulosic substrates.